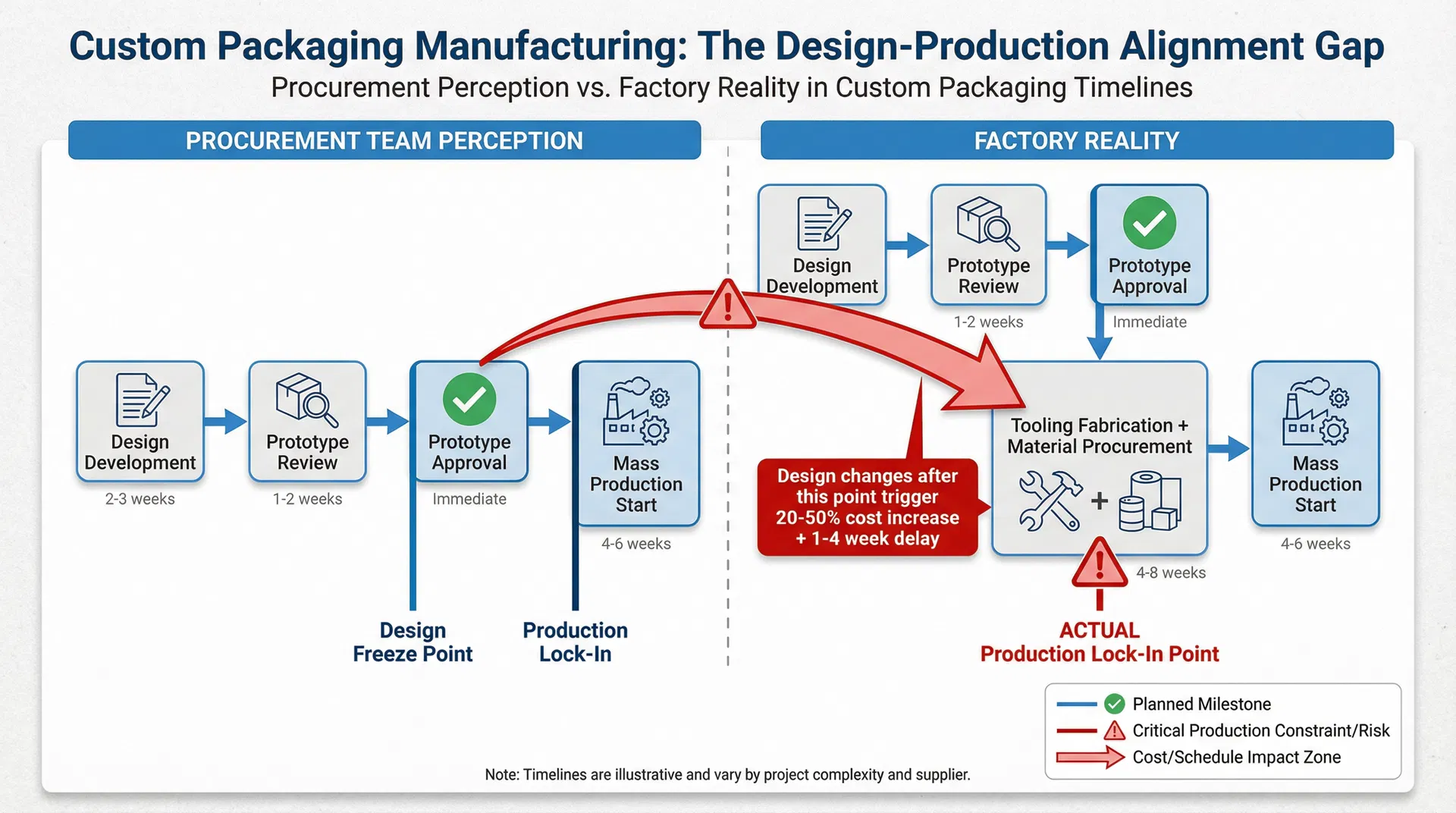

When procurement teams commission custom corporate gift boxes for UAE enterprises, the approval workflow typically follows a familiar sequence: requirement definition, supplier quotation, design development, prototype review, prototype approval, and mass production. The prototype approval milestone is widely understood as the "final checkpoint" for design validation—the moment when stakeholders confirm that the physical sample meets expectations and production can proceed without further adjustments.

This understanding is where the misjudgment begins. Prototype approval does not function as a design freeze in the way procurement teams assume. In practice, it represents the beginning of a high-risk window during which design changes transition from manageable adjustments to production-disrupting interventions that trigger tooling obsolescence, material waste, and timeline extensions that were never factored into the original project schedule.

The core issue is not that procurement teams lack diligence in reviewing prototypes. Rather, it is that the cost structure of custom packaging does not align with the approval timeline that procurement teams intend to follow. Design changes that appear "minor" or "cosmetic" after prototype approval—adjusting a logo placement by 8mm, switching from matte to gloss lamination, or revising the magnetic closure mechanism—require the supplier to discard completed tooling, reorder materials that have already been procured, and reschedule production runs that have been locked into the factory's capacity plan. The result is a cost and timeline impact that is disproportionate to the perceived scope of the change.

From a factory project management perspective, this pattern repeats with predictable regularity. A procurement team submits an "approved" design, the factory begins tooling fabrication and material procurement, and two to three weeks into production preparation, the client requests "small changes" that necessitate a complete restart of the tooling setup. The procurement team views these changes as refinements that should be accommodated within the quoted lead time and budget. The factory views them as scope changes that invalidate the work completed to date and require a new production cycle with associated costs and delays.

The disconnect stems from a fundamental misunderstanding of when production lock-in occurs. Procurement teams believe that production lock-in happens when mass production begins—when the first batch of gift boxes rolls off the assembly line. In reality, production lock-in occurs much earlier, at the point when the factory commits resources to tooling fabrication and material procurement based on the approved prototype. Once dies are cut, plates are engraved, and materials are ordered to match the prototype specifications, any design change forces the factory to absorb sunk costs or pass those costs back to the client in the form of revision fees that were never budgeted.

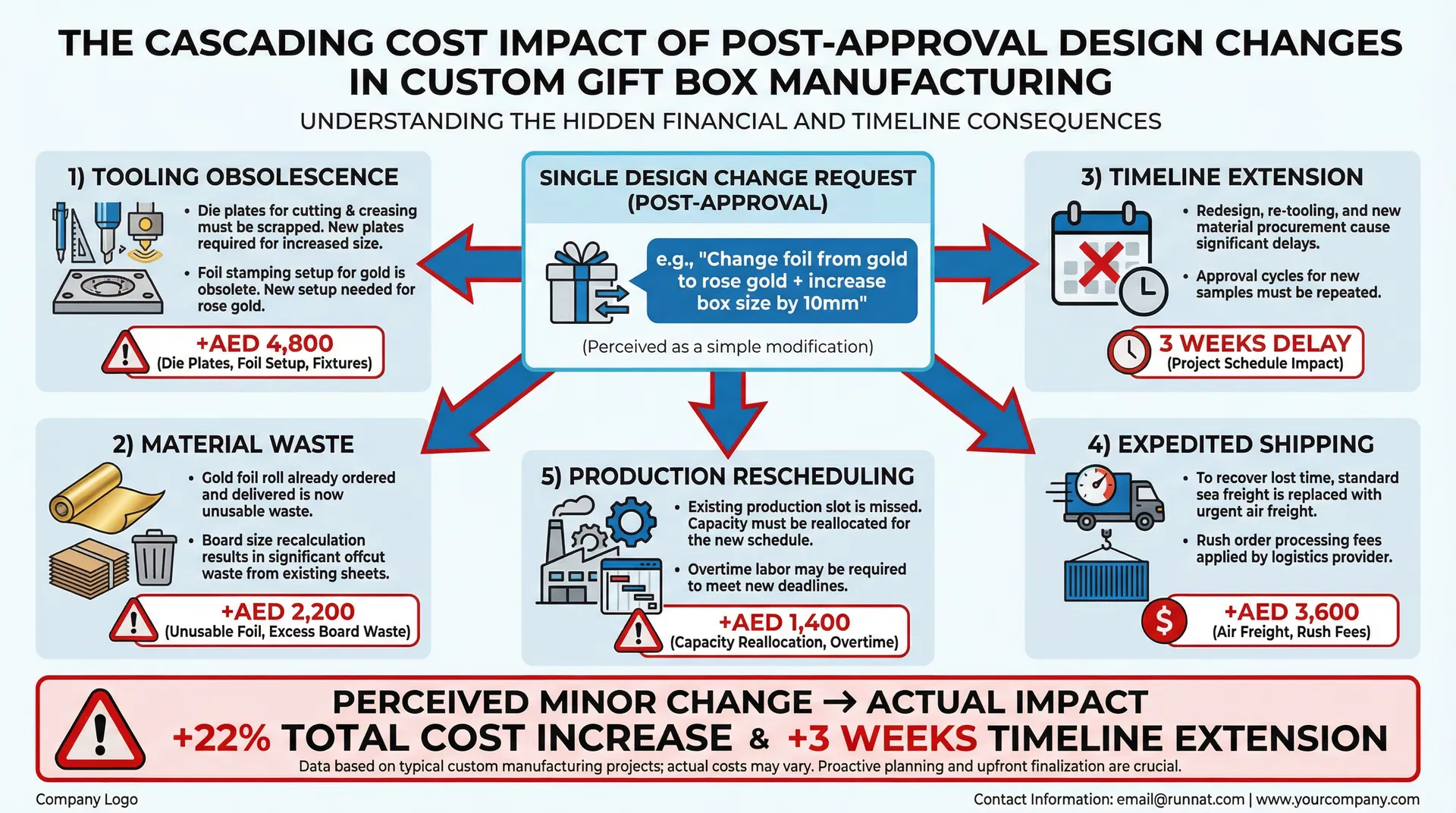

Consider a representative scenario from UAE corporate gifting. A procurement manager commissions 5,000 custom rigid gift boxes with magnetic closure, soft-touch lamination, and foil-stamped branding for a year-end client appreciation program. The supplier provides a prototype that meets the visual and structural requirements, and the procurement team approves it for mass production. Three weeks later—during the tooling setup phase—the marketing team requests a design adjustment: the foil stamping should shift from gold to rose gold, and the box dimensions should increase by 10mm to accommodate a larger gift item.

The procurement team views these changes as reasonable refinements that emerged from internal stakeholder feedback after the prototype was circulated more widely within the organization. The supplier quotes an additional AED 4,800 in tooling revision fees and a three-week timeline extension. The procurement team is surprised by the cost and delay, as the changes appear minor compared to the original scope of work.

What the procurement team does not see is the cascading impact of these changes on the factory's production workflow. The original tooling—dies for cutting the box structure, plates for foil stamping, and setup configurations for the magnetic closure assembly—has already been fabricated based on the approved prototype. The gold foil material has been ordered and is in transit. The production schedule has been locked, with machine time allocated and labor resources assigned. Changing to rose gold foil requires the supplier to cancel the gold foil order (incurring cancellation fees or absorbing the cost of unusable inventory), source rose gold foil from a different supplier (which may have longer lead times), and re-engrave the foil stamping plates to match the new material's heat transfer characteristics. Increasing the box dimensions by 10mm requires new dies to be cut, new material calculations to be performed (as the larger dimensions consume more board per unit), and the magnetic closure mechanism to be re-tested for structural integrity at the new size.

Each of these adjustments, taken individually, may add only three to five days to the production timeline. But they do not occur in parallel—they occur sequentially, as each change depends on the completion of the previous adjustment. The foil material must be sourced before the plates can be tested. The new dies must be fabricated before material quantities can be finalized. The magnetic closure must be re-tested before assembly workflows can be confirmed. The cumulative delay extends the timeline by three weeks, and the cumulative cost—tooling revision, material waste, expedited sourcing fees, and production rescheduling—adds 18–22% to the original quote.

The financial impact extends beyond the direct revision fees. The three-week delay pushes the delivery date past the client appreciation program's target distribution window, forcing the procurement team to choose between two unfavorable options: delay the gifting program (which undermines the relationship-building objective) or pay expedited shipping fees to recover the timeline (which adds another 12–15% to the total project cost). Neither option was contemplated when the original budget was approved, and both represent avoidable expenses that could have been prevented with earlier design freeze discipline.

The misjudgment is compounded by a phenomenon that factory project managers refer to as "approval fatigue." Stakeholders who approve the prototype often request changes during production because they did not fully visualize the final product during the prototype review. The prototype is evaluated in isolation—examined on a conference table, photographed for internal circulation, and assessed against brand guidelines. But it is not evaluated in the context of the actual gifting scenario: how the box will appear when stacked in bulk shipments, how the foil stamping will catch light in the recipient's office environment, how the magnetic closure will feel after repeated opening and closing by the end user.

When the procurement team later visualizes these use cases—often prompted by feedback from sales teams, regional offices, or executive leadership—they identify refinements that "should have been obvious" during the prototype review but were not apparent at the time. The result is a revision request that the procurement team views as a necessary correction and the factory views as a scope change that invalidates the approved design.

This pattern is not unique to UAE corporate gifting, but it is particularly pronounced in markets where corporate gift programs are tied to specific events with fixed timelines—Ramadan gifting, year-end client appreciation, new office openings, or VIP relationship milestones. These programs operate under non-negotiable delivery deadlines, and any timeline extension created by post-prototype revisions directly threatens the program's success. Yet procurement teams continue to approve prototypes without establishing a formal design freeze, assuming that the supplier will accommodate "reasonable" refinements as part of the standard production process.

The systematic error in design approval timing stems from a mismatch between the decision-making frameworks that procurement teams apply and the production realities that suppliers navigate. Procurement teams are trained to minimize per-unit costs, negotiate favorable payment terms, and maintain flexibility to accommodate stakeholder feedback. These priorities are appropriate for commodity purchasing, where suppliers hold inventory and can adjust orders without disrupting production workflows. But they are misaligned with custom packaging production, where every design element is fabricated to order and changes after prototype approval trigger sunk costs that cannot be recovered.

The solution is not to eliminate post-prototype revisions entirely—some design adjustments are genuinely necessary to address issues that only become apparent during prototype evaluation. Rather, the solution is to establish a formal design freeze before prototype approval, not after. This requires procurement teams to invest more time in stakeholder alignment during the design development phase, ensuring that all decision-makers—marketing, legal, procurement, and executive leadership—have reviewed and approved the design concept before the supplier fabricates the prototype.

A formal design freeze functions as a contractual commitment: once the design is frozen, any subsequent changes are treated as out-of-scope modifications that trigger additional costs and timeline extensions. This clarity prevents the "minor tweak" fallacy, where procurement teams request small changes without understanding the cascading impact on tooling, materials, and production scheduling. It also creates accountability for stakeholders who request changes after the freeze, as they must justify the cost and timeline impact against the benefit of the proposed adjustment.

In practice, establishing a design freeze before prototype approval requires procurement teams to adopt a different approval workflow. Instead of treating the prototype as the first opportunity for stakeholders to evaluate the design, the prototype should serve as a validation checkpoint for a design that has already been thoroughly reviewed and approved in digital form. This means circulating 3D renderings, conducting virtual design reviews, and securing sign-off from all stakeholders before the supplier invests resources in prototype fabrication.

The UAE market presents additional complexity due to bilingual requirements (Arabic and English), cultural sensitivities around imagery and color symbolism, and regulatory compliance requirements for certain gift categories. These factors increase the likelihood that stakeholders will identify issues during prototype review that were not apparent during digital design review. But they do not eliminate the need for design freeze discipline—they reinforce it. The more complex the design requirements, the more critical it becomes to invest time in stakeholder alignment before prototype approval, rather than relying on the prototype as the primary design validation mechanism.

The cost of post-prototype revisions is not merely financial. It also includes reputational risk. Suppliers who experience repeated revision requests from the same client begin to build contingency buffers into future quotes, anticipating that the "approved" design will change during production. This increases the per-unit cost for all subsequent orders, as the supplier prices in the risk of scope changes. Procurement teams who develop a reputation for requesting post-prototype revisions also find that suppliers become less willing to accommodate tight timelines or offer favorable payment terms, as the supplier views the client as a high-risk account that is likely to disrupt production workflows.

The systematic misjudgment of design approval timing is not a failure of individual procurement managers. It is a structural issue that emerges from the way corporate procurement processes are designed. Procurement teams are evaluated on cost savings, supplier negotiation outcomes, and adherence to budget constraints. They are not typically evaluated on design freeze discipline, stakeholder alignment efficiency, or the ability to prevent post-approval revisions. Until procurement performance metrics are adjusted to reward early design freeze discipline, the pattern of post-prototype revisions will continue to generate avoidable costs and timeline extensions across the UAE corporate gifting market.

For procurement teams navigating custom corporate gift box specifications, the critical insight is that prototype approval should not be treated as the final checkpoint for design validation. It should be treated as the beginning of production lock-in, after which design changes become prohibitively expensive. The time to refine the design is before prototype approval, not after. The stakeholders who need to provide input are the same stakeholders who will request changes during production if they are not consulted early enough. And the cost of investing more time in design freeze discipline before prototype approval is far lower than the cost of absorbing revision fees, timeline extensions, and expedited shipping charges after production has begun.