When procurement teams execute custom gift box projects, they frequently misjudge "stakeholder review completion" as equivalent to "stakeholder alignment." This misjudgment stems from a fundamental misunderstanding of the approval workflow's true nature—mistaking an information distribution mechanism for a consensus-building mechanism. When procurement teams design review workflows, they typically focus on ensuring all relevant departments have "seen" the design proposal, without confirming whether these departments truly understand the proposal's technical constraints, cost implications, and operational realities.

This misjudgment is particularly dangerous in custom gift box projects because box design simultaneously involves brand marketing, product protection, logistics distribution, and cost control across multiple dimensions. When the marketing department approves a "visually perfect" design, they may not realize that the special materials required will increase unit costs by 40%. When the finance department approves the budget, they may not understand that the magnetic closure mechanism in the design requires additional structural testing, extending the timeline by two weeks. When the logistics team finally sees the finished product, they discover that the box dimensions cannot efficiently utilize standard shipping pallets, increasing freight costs by 25%.

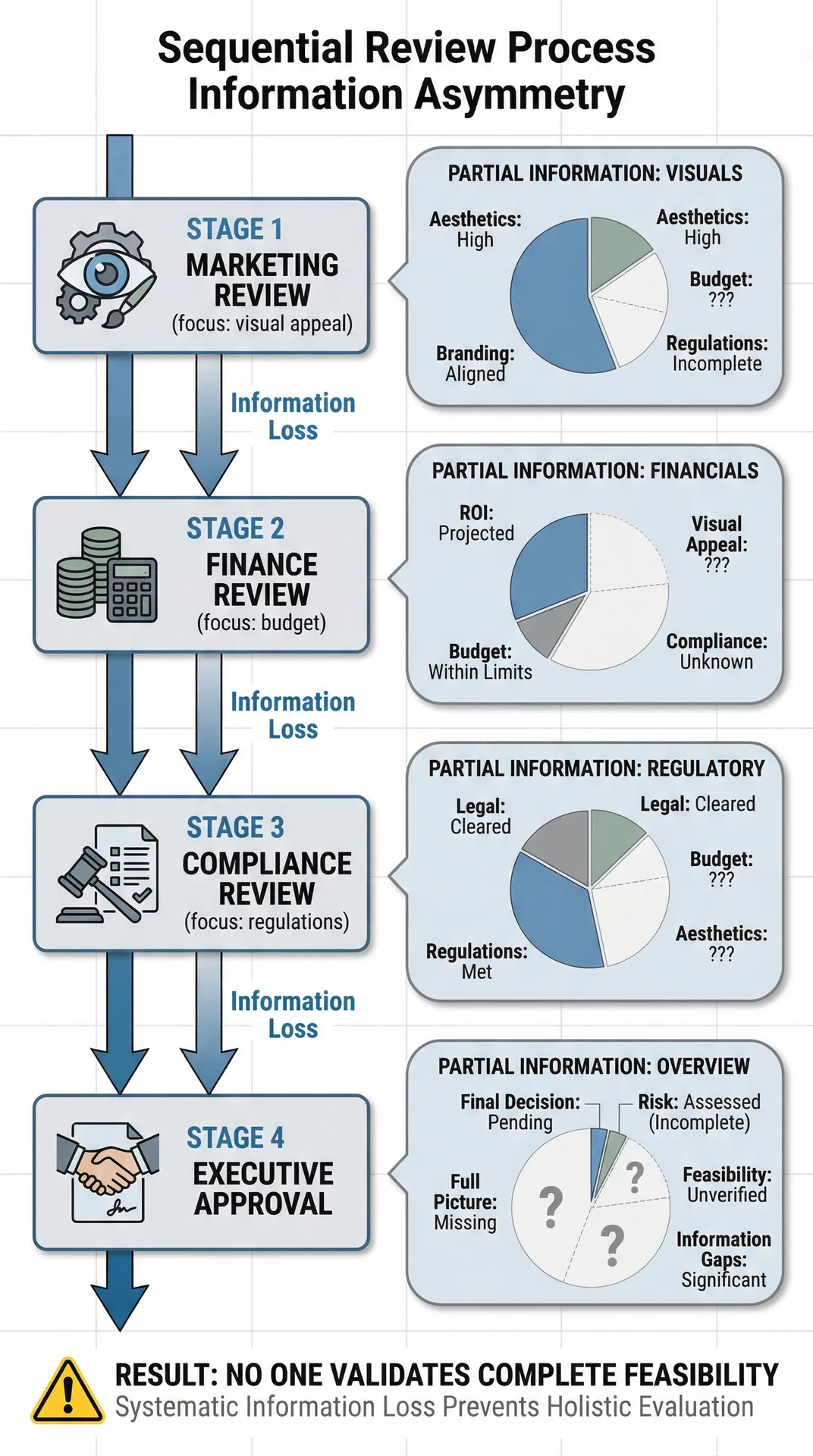

In practice, this misjudgment typically forms through the following process. The procurement team establishes what appears to be a comprehensive review workflow: the design proposal is first reviewed by the marketing department for visual presentation, then by the finance department for budget reasonableness, followed by the regulatory team for compliance, and finally by senior management for final approval. Each review node has clear sign-off forms and deadline requirements. From a process management perspective, this mechanism seems to have covered all necessary stakeholders. However, this workflow design overlooks one critical fact: sequential review mechanisms systematically amplify information asymmetry.

When the marketing department reviews the design in the first stage, they make judgments based on brand consistency and visual appeal, but they cannot foresee that the finance department will request cost reductions in the second stage. When the finance department reviews the budget, they make judgments based on unit costs and total budget, but they cannot foresee that the regulatory team will require material substitutions in the third stage to meet food contact safety standards. When the regulatory team reviews compliance, they make judgments based on certification scope and testing requirements, but they cannot foresee that the logistics team will discover during execution that the packaging dimensions do not conform to the warehousing system's standardization requirements.

Each reviewer makes a "correct" judgment within their professional domain, but these judgments are based on incomplete information. More dangerously, later-stage reviewers often assume that earlier-stage reviewers have already validated basic feasibility, so they only focus on details within their own professional domain. This assumption creates systematic blind spots—no one is responsible for validating the overall solution's executability across all dimensions.

Another common mistake procurement teams make is treating the review stage as a "decision stage" while ignoring the implicit production preparation activities that suppliers have already begun during the review period. When procurement teams send design proposals to suppliers for quotation, suppliers do not wait until all internal reviews are complete before starting preparation. They immediately begin evaluating tooling requirements, contacting material suppliers, and reserving production line slots. If the procurement team spends three weeks on the review process and the finally approved design differs significantly from the initial proposal, the supplier's preparatory work may be completely wasted. These implicit costs do not appear on the procurement team's budget sheet, but they surface in the form of "supplier quotes suddenly increasing" or "delivery schedules becoming unachievable."

The deeper problem is that the review workflows designed by procurement teams typically only include "decision-layer" stakeholders while systematically ignoring "execution-layer" operational constraints. Marketing directors, finance directors, and regulatory directors are all in the review workflow, but warehouse managers, distribution supervisors, and customer service team leaders typically are not. The operational knowledge held by these execution-layer personnel—such as existing warehousing systems can only handle packages within specific size ranges, distribution teams' staffing cannot handle heavy gift boxes requiring special handling, and customer service teams lack the capability to answer questions about complex opening mechanisms—is completely ignored during the review stage. When these operational constraints surface during the execution stage, the project team faces only two choices: either accept significant efficiency losses and cost increases, or redesign and bear the consequences of tooling obsolescence and schedule delays.

This misjudgment also produces a more insidious consequence: it cultivates an "approval fatigue" culture. When stakeholders discover that their opinions raised during the review stage are frequently ignored due to conflicts with other departments' priorities, they gradually lose motivation to participate in reviews. They begin to view reviews as a formalized sign-off procedure rather than an opportunity to genuinely influence decisions. This fatigue leads stakeholders to adopt a "defensive approval" strategy during reviews—they attach numerous disclaimer clauses and reservations to sign-off forms to ensure they will not be held accountable when projects encounter problems. These reservations are typically worded vaguely, such as "need to confirm this design's feasibility in actual production" or "recommend complete functional testing before mass production." These comments legally protect the reviewer, but they provide no substantive help to project execution because they do not identify specific risk points or provide actionable recommendations.

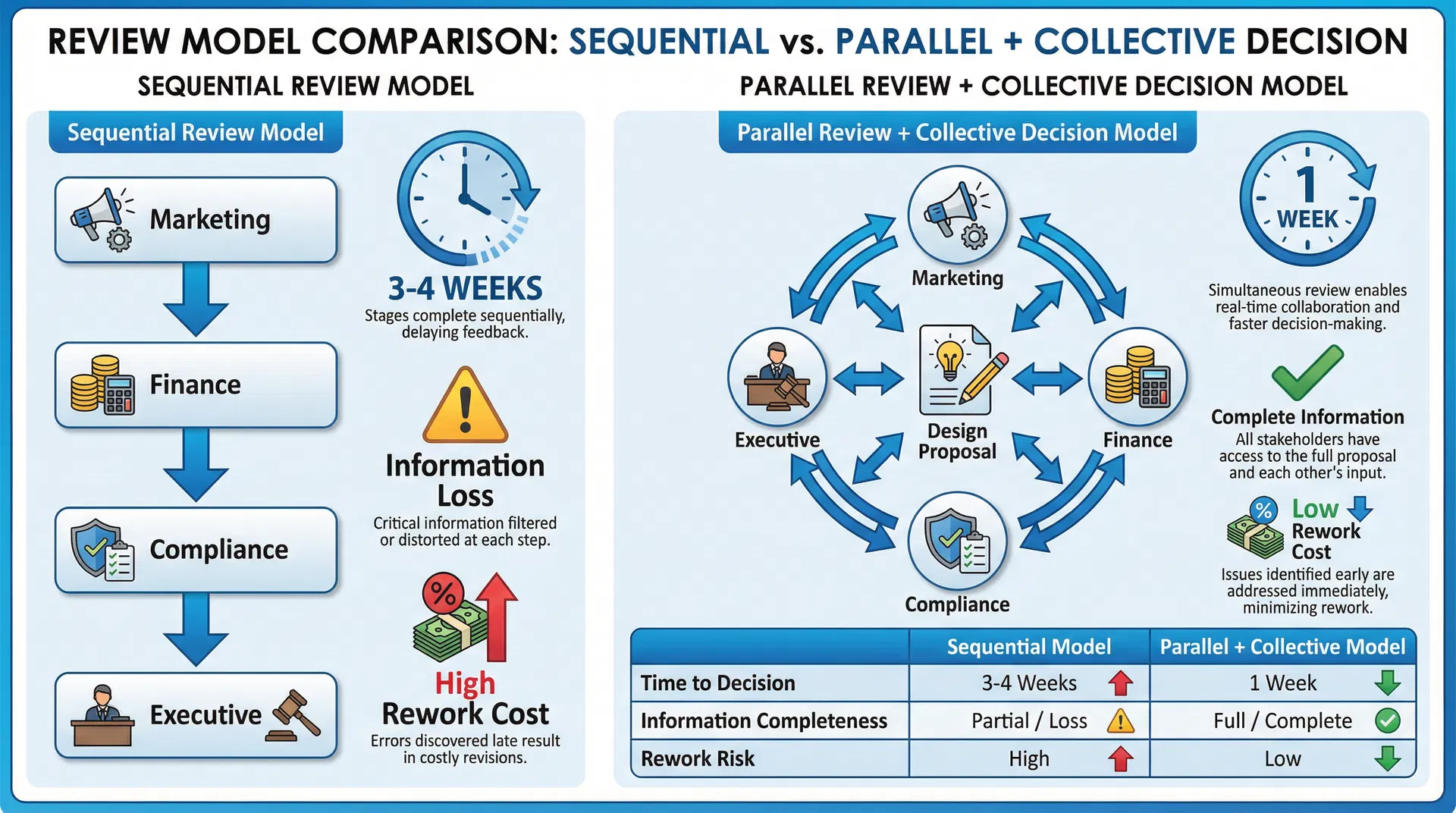

When navigating the complex decision environment of custom gift box customization, procurement teams need to recognize that approval workflow design itself is a strategic decision. An effective review mechanism should not merely be a channel for information distribution but rather a platform for consensus building. This means the review workflow needs to include three key elements: First, all stakeholders need to access complete information at the same point in time, rather than making judgments based on fragmented information at different stages. Second, the review workflow needs to explicitly identify and resolve priority conflicts between different departments, rather than deferring these conflicts to surface during the execution stage. Third, the review workflow needs to incorporate execution-layer operational knowledge to ensure the approved solution is executable across all dimensions.

In practice, this may mean procurement teams need to abandon the traditional sequential review model and instead adopt a "parallel review plus collective decision-making" model. In this model, all stakeholders review the design proposal in the same meeting and discuss their respective constraints and priorities in real time. The execution cost of this model is indeed higher—it requires coordinating the time of multiple department heads, and the meeting process may be filled with conflicts and debates. But the cost of this upfront investment is far lower than the cost of later changes and rework. More importantly, this model can ensure that the finally approved solution is based on consensus among all stakeholders, rather than just an accumulation of individual departments' one-sided judgments.

Procurement teams also need to redefine the standard for "review completion." Review completion should not simply be "all sign-off forms have been signed," but rather "all stakeholders understand and commit to supporting the execution of this solution." This means the output of the review workflow should not merely be a sign-off record but rather a clear execution commitment document that lists the resources each department needs to provide during the project execution stage, the schedules they need to adhere to, and the responsibilities they need to assume. This commitment document can transform discussions during the review stage into action guidelines for the execution stage and provide clear accountability basis when projects encounter problems.

Ultimately, procurement teams need to recognize that the success of custom gift box projects does not depend on how exquisite the design is or how competitive the price is, but rather on whether all stakeholders are truly aligned. The purpose of the review workflow is not to collect signatures but to build consensus. When procurement teams view the review workflow as an opportunity for consensus building rather than a channel for information distribution, they can truly reduce risks during the project execution stage and ensure that custom gift box projects achieve their objectives across all dimensions including budget, schedule, and quality.